Miniature Fiber Optic Pressure Sensors Based on Polymer Process

Miniature

Fabry-Perot (FP) pressure sensors have been of great interest because of their

advantages of small sizes, high performance, and immunity to electromagnetic

interference. Most of these sensors are built with silicon/silica materials

that have good mechanical, chemical, and thermal stabilities. However, due to

the large elastic modulus of silica/silicon, developing a high sensitivity

miniature sensor becomes difficult. In addition, fabrication of these sensors

often involves high temperature fusion bonding and harsh acid etching. On the

other hand, to realize high sensitivity, miniature pressure sensors, a polymer

material becomes an attractive choice since its Young’s modulus is

significantly smaller than that of silicon/glass. Moreover, polymer processes

can be performed under ambient pressure and temperature without hazardous

chemicals. However, a significant drawback of a

polymer-based sensor is the high temperature sensitivity, which must be

compensated to obtain accurate pressure measurements.

Miniature temperature Compensated Fabry Perot Pressure Sensor Fabricated with Self-aligned Photolithography Process [1, 2]

-

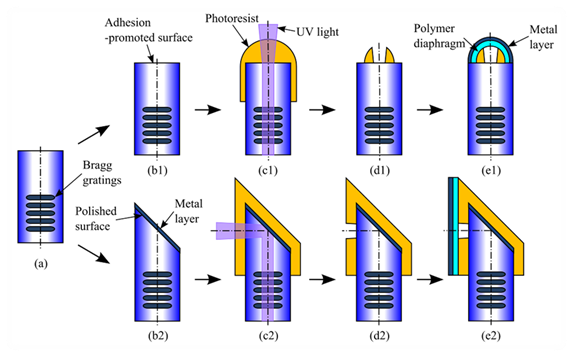

Since

there are many available processing techniques that can be used for polymer

materials and performed in ambient pressure and temperature, sensor fabrication

can be easy by using these processes. In this work, fiber optic Fabry-Perot

sensor fabricated by using a self-aligned photolithography technique is

presented. Instead of using the conventional mask and mask aligner for the

photolithography process, an optical fiber waveguide is used to couple UV light

for exposing and defining the optical cavity. This low-cost fabrication

technique offers self-aligned property for sensor fabrication. Fiber Bragg

gratings were embedded in the sensors to measure temperature and compensate

temperature effect on the polymer cavities. Figure 1 illustrates the

fabrication process of two types of sensors (i.e.: co-axial and cross-axial

sensors) fabricated with the self-aligned photolithography. The cavities

defined by the self-aligned photolithography were covered with another

UV-curable polymer layer and thin metal layer. This polymer/metal composite

layer was used as a pressure sensitivity layer for pressure measurements. The

cross-axial sensor configuration has surface-mountable capability when a

surface-flow should be avoided in pressure measurements.

Figure 1: Fabrication process of co-axial and cross-axial sensors

-

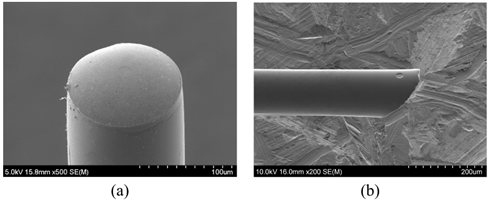

Scanning

electron micrographs of the fabricated co-axial and cross-axial sensors are

shown in Figure 2.

Figure 2: Scanning electron micrographs of fabricated sensors: (a) co-axial sensor and (b) cross-axial sensor.

Miniature Temperature Compensated Fabry-Perot Pressure Sensor Created by Using UV-molding process with an Optical Fiber Based Mold [3]

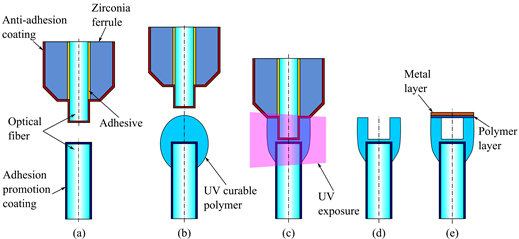

UV-molding

process (or UV imprinting process) is one of fabrication processes that make

use of a UV curable polymer. The process usually consists of several steps

including master pattern fabrication, mold fabrication, dispensing/exposure,

and demolding. If a master pattern is used as a mold, the first step can be

omitted. This process has been applied to fabricate various optical elements

with small features, which allows for enhanced thermo-mechanical stability, low

birefringence, and low-cost. In this work, a Fabry-Perot (FP) pressure sensor

with built-in temperature measurement and compensation capability is designed

and fabricated based on a UV-molding process and the metal-polymer composite

thin film fabrication method described previously. Figure 3 illustrate the

fabrication process of the sensor.

Figure 3: Fabrication process of UV-molded fiber optic pressure sensor.

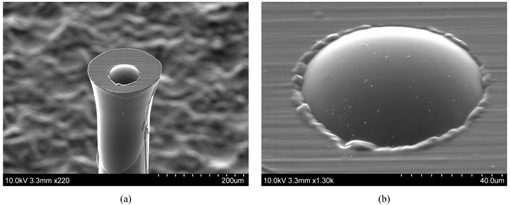

The

sensor is composed of a UV-molded optical cavity and a polymer-metal composite

diaphragm, which is fabricated at the end of a single mode fiber with a

pre-written fiber Bragg grating, rendering the sensor the capability of

temperature compensation and simultaneous measurement of pressure and

temperature. The mold used for UV-molding process is built by assembling a

polished ferrule and a cleaved optical fiber, which eliminates the need for a

costly semiconductor or direct machining process and enables high accuracy

optical alignment of the mold and the sensing fiber. The sensor fabrication

follows simple, repeatable processes and safe procedures, and uses less

expensive materials and equipment. This fabrication method can also be used for

batch fabrication or wafer scale fabrication with minor modifications to the

processes. Scanning electron micrographs of the fabricated co-axial and

cross-axial sensors are shown in Figure 4.

Figure 4: SEM images of (a) fabricated sensor and (b) diaphragm close-up.

Publications on this work

[1] Bae,

H., Zhang, X. M., Liu, H., & Yu, M., ”Miniature

surface-mountable Fabry-Perot pressure sensor constructed with a 45 degree angled

fiber,” Optics

Letters, 35(10), 1701–1703 (2010).

[2]

Bae, H., Dunlap, L., Wong, J., & Yu, M., “Miniature Temperature Compensated

Fabry – Perot Pressure Sensors Created With Self-Aligned Polymer

Photolithography Process,” IEEE Sensors Journal, 12(5) (2012).

[3]

Bae, H., & Yu, M., “Miniature Fabry-Perot pressure sensor created by using

UV-molding process with an optical fiber based mold,” Optics Express, 20(13),

(2012).

Copyright by Sensors and Actuator Lab

Last updated on September 10th, 2010